Product Description

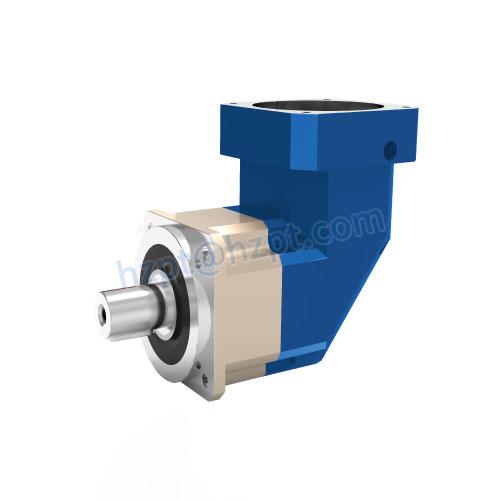

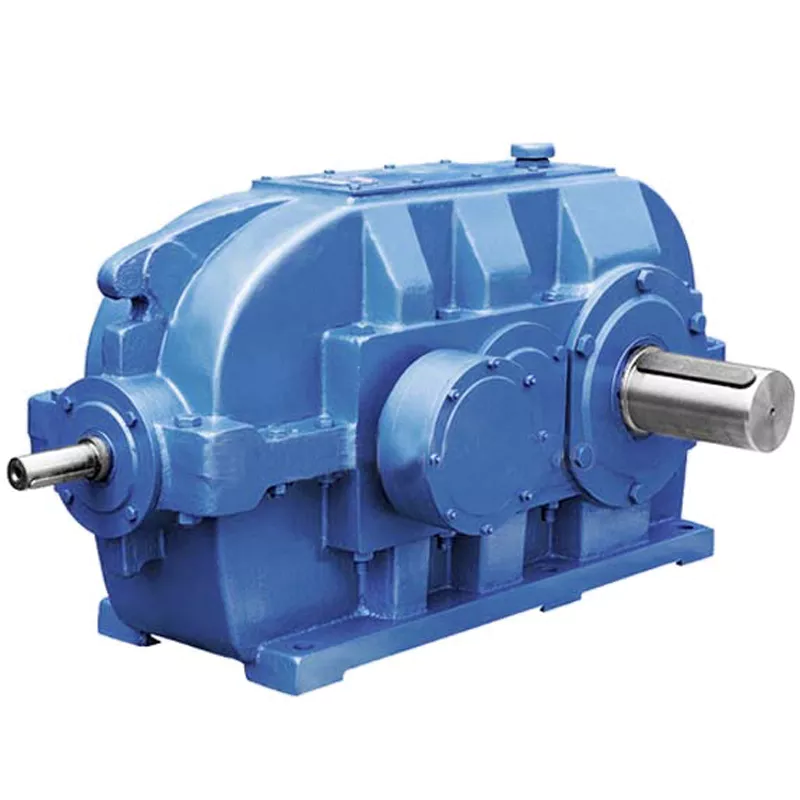

Automated Assembly Line Flange Mounting Motor Brake 220V 380V 90 Degree Km Hypoid Vertical Helical Bevel Gear Conveyor Motor Gearbox

| Housing | Nodular Cast Iron(Ductile Iron) QT600 |

| Gears Profile | Hardened Helical Gears |

| Gears Material | 20CrMnTi |

| Gears Processing | Carburizing, Quenching, Grinding |

| Gears Hardness | Surface Hardness: HRC58-62, Inner Hardness: HBS156-207 |

| Gears Accuracy | 6 Class |

| Shafts Material | 40Cr |

| Input Configurations | Keyed CHINAMFG Shaft Input IEC Normalized Motor Flange |

| Output Configurations | Keyed Hollow Shaft Output |

| Oil Seal | ZheJiang SOG |

| Bearings | NSK, SKF, HRB, ZWZ, LYC |

| Spare Parts | Torque arm, Optional Backstop |

Please click here for more types!

Our Services

With all our activities DNV-ISO 9001, SGS -certified, we stand for top-quality service. Entrusting your gearboxes to the care of our Services.

Help protect your gearbox from wear and grinding, SGR gearbox converts torque reliably and efficiently.

We customize our CHINAMFG planetary gear units, double enveloping worm gearbox, helical gear motor, modular design helical gear unit, worm gearbox, cycloidal gearbox etc to fit your application and meet your needs.

These features enable a reliable and safe service life of over 200 000 operational hours.

Our customers have been placing their trust in CHINAMFG gear units since 1997. More than 500 000 gear units of our gearbox are in use reliably around the world, in many cases under very harsh conditions.

Related Products

For more reducers and mechanical accessories, please click here to view

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Speed Changing, Speed Reduction |

| Layout: | Helical Gearbox |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Stepless |

| Customization: |

Available

| Customized Request |

|---|

Examples of Vehicles and Equipment Using 90 Degree Gearboxes

90 degree gearboxes are commonly used in various vehicles and equipment where a change in direction of power transmission is required. Here are some examples:

- Automobiles: Many vehicles use 90 degree gearboxes to transmit power from the engine to the wheels, especially in front-wheel drive configurations where the engine is mounted transversely.

- Construction Machinery: Equipment like excavators and loaders use 90 degree gearboxes to change the direction of power in hydraulic systems that control movements.

- Agricultural Equipment: Tractors and combines often employ 90 degree gearboxes to transfer power from the engine to various components like the drivetrain and attachments.

- Marine Applications: Boats and ships use 90 degree gearboxes to change the direction of propulsion power from the engine to the propellers.

- Industrial Machinery: Many industrial machines use 90 degree gearboxes to transmit power in different directions, enabling complex movements and operations.

- Printing Presses: Printing presses often use 90 degree gearboxes to change the direction of power transmission between different sections of the machine.

- Textile Machinery: Textile manufacturing equipment may use 90 degree gearboxes to change the direction of power for various processes.

- Material Handling Equipment: Conveyor systems and other material handling equipment use 90 degree gearboxes for changing the direction of movement.

- Robotics: Robotic arms and mechanisms often utilize 90 degree gearboxes to achieve precise movements and positioning.

- Food Processing Equipment: Machinery used in food processing may use 90 degree gearboxes to change the direction of power transmission in various stages of production.

These examples highlight the versatility and importance of 90 degree gearboxes in a wide range of applications across different industries.

Cost Range for Different Types of 90 Degree Gearboxes

The cost of different types of 90 degree gearboxes can vary widely depending on various factors, including the gearbox design, quality, brand, and intended application. Here’s a general cost range for different types:

- Spur Gearboxes: Spur gear 90 degree gearboxes are relatively simple in design and often more affordable. Their cost can range from $50 to $300.

- Bevel Gearboxes: Bevel gear 90 degree gearboxes are more complex and versatile, leading to a higher cost range. They typically range from $100 to $800 or more.

- Worm Gearboxes: Worm gear 90 degree gearboxes are efficient and provide high torque, but they tend to be more expensive due to their precision. Their cost can range from $200 to $1000 or more.

- Planetary Gearboxes: Planetary gear 90 degree gearboxes offer excellent torque transmission and compact size, making them suitable for various applications. They are often higher in cost, ranging from $300 to $1500 or more.

It’s important to note that these cost ranges are approximate and can vary based on factors such as size, gear quality, ratio options, and additional features. Customization, brand reputation, and specific industry requirements can also impact the cost of a 90 degree gearbox.

Changing Direction with a 90 Degree Gearbox

A 90 degree gearbox, also known as a right-angle gearbox, is designed to change the direction of rotational motion by 90 degrees. It accomplishes this by utilizing a set of gears and shafts arranged in a specific configuration. Here’s how the concept of changing direction works:

Imagine two shafts arranged perpendicular to each other. The input shaft, connected to the source of power, transfers rotational motion to a set of gears inside the gearbox. These gears transmit the motion to an intermediate shaft, which is positioned at a right angle to the input shaft.

The intermediate shaft, in turn, transfers the motion to another set of gears, which are designed to mesh with the gears on the output shaft. The output shaft is aligned parallel to the input shaft but positioned at a right angle to the intermediate shaft. This arrangement of gears and shafts allows the rotational motion to be redirected by 90 degrees.

The gears used in a 90 degree gearbox are typically bevel gears or worm gears, which are specifically designed to transfer motion at right angles. Bevel gears have cone-shaped teeth that mesh at an angle, while worm gears consist of a helical gear (worm) that meshes with a worm wheel to achieve the required direction change.

Overall, a 90 degree gearbox provides a compact and efficient solution for changing the direction of motion, making it invaluable in various applications across industries.

editor by CX 2024-04-24