Product Description

Product Description

Detailed Photos

The NMRV reducer is relatively light in weight, and the shell is made of aluminum alloy. It has the advantages of light weight, superior strength, beautiful appearance, high heat dissipation performance, long service life, no noise in action, etc. It is convenient and simple to connect with the motor. Easy to install. NMRV reducer is a more practical transmission equipment, and its appearance design and body are more in line with the needs of the public than other types of reducers. Although the RV reducer made of aluminum alloy only emerged in 2007, its application field and popularity are even better than other types of reducers. It is a reducer with high practicability. , but also the integration of advanced technology at home and abroad. The NMRV reducer is extremely convenient to connect with ordinary motors, continuously variable transmissions, and flanged electromagnetic clutch brakes, and does not require couplings to connect. It is suitable for all-round installation, and the output torque is relatively large, and the work is quite stable.

Editing and broadcasting of main materials

1. Body, die-casting aluminum alloy;

2. Worm shaft, 20 Crq steel, high temperature treatment;

3. Worm gear, nickel bronze alloy;

4. Aluminum alloy body, sandblasting and surface anti-corrosion treatment;

5. Cast iron body, painted with bIu RA5571.

Regular center distance specification editing and broadcasting

Center distance: 130 (unit: mm).

Output hole/shaft diameter: 11, 14, 18, 25, 28, 35, 42, 45 (unit: mm)

Advantage: ♠ Occupied no space: The space requirement for the installation of output shaft is considerably large while assembling motor or reduce. The installation of hollow type reducer may form right Angle with motor,thus facilitate miniaturize of the machine

♠ Self-locking: For the place require for minor holding force,save the costof baking device,such as in slope conveyor ♠ Fast stop: The ordinary gear reducer available in market requires 5-10seconds stop time. but NRV series product need only 2-5 seconds to reach state of still. ♠ High accommodation:You may select from hollow shaft. uni-direction output shaft or dal output shaft, easy to modify, only 1 minute to complete the dissemble and assemble of shaft. ♠ High safety: Use transmission different from conventional method, no sprocket pulley is needed,no exposed

transmission structure, Reduce the possibility of operator ♠ Good protection: Water, dust proof,the protection class Ip55 possesses,good isolation to dust and moisture

♠ Allow multiple sides installation,no restriction in angle: There are holes for mounting on all plains of the series of

product for your selection of direction and angle required.

♠ Good cooling effect: One formation aluminum alloy for casing, quigley heat dissipation extended life for worn lever, worn gear, good durability(wormca-sing during running is normal)

♠ Easy maintenance: Different from conventional mounting method,you den’t need the dissemble the sprocket, pulley but only dissemble and Assemble the mounting base of the reducer to compete the modification easily.

♠ No restriction on motor brand: Match with 15W-200W motor or domestic product available in market without further processing.

♠ Wide reduction ratio: Easily change the reduction ration from 30-20000 due to detached assemble.

♠ May complete with brake,clutch in 1 formation aesthetic and practice.

Main fetures:

1. Large speed ratio range 2. Small volume,low weight ,saving space for mounting. 3. Self-locking

4. High cost performance

5. Suitable for various motors

Use and safety guarantee

1. Please check and confirm the matching intensity between worm gear reducer and mechanical equipment before use to assure that it is in the safety range of worm gear reducer performance parameters

2. Worm gear reducer has filled with WA460 lubricating oil. Please replace the lubricating oil after the first starting of 400 hours and after then 4000 hours for lubricating oil replacing cycle

3. There should be enough lubrication in worm gear box and keep regular check with the oil level.

4. When installation. please be careful to avoid sharp instruments bruising the oil seals on output shaft to cause leakage

5. Please confirm the rotation direction before mechanical connection. If the rotation direction is not correct, it will possible injury or damage the devices

6. Please set safety covers in rotating position to avoid of injuring

7. Please pay full attention: it is very dangerous if there is off or falling when moving

Packaging & Shipping

Company Profile

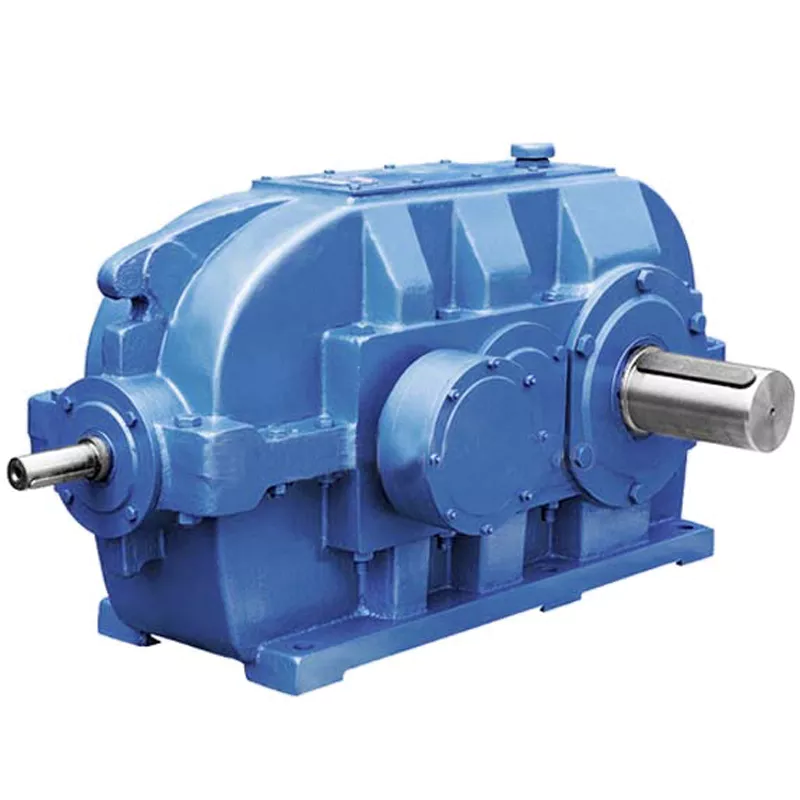

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | 90 Degree |

| Layout: | Expansion |

| Gear Shape: | Cylindrical Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | Using 90 Degree Gearboxes in High-Speed and High-Torque ApplicationsYes, 90 degree gearboxes can be used in both high-speed and high-torque applications. The choice of gearbox type and design depends on the specific requirements of the application. For high-speed applications, gearboxes with suitable gear ratios and efficient designs, such as planetary gearboxes, can provide the necessary speed output while maintaining efficiency. On the other hand, for high-torque applications, worm gearboxes and bevel gearboxes are commonly used due to their ability to handle heavy loads and transmit high levels of torque efficiently. Request Sample |

|---|

Choosing the Right Size 90 Degree Gearbox

Choosing the right size

Benefits of Using a 90 Degree Gearbox in Machinery

A 90 degree gearbox offers several advantages when used in machinery and mechanical systems:

- Space Efficiency: The compact design of a 90 degree gearbox allows for changes in direction without the need for extra space. This is particularly beneficial in tight or constrained environments.

- Change of Direction: A primary advantage is the ability to change the direction of rotational motion by 90 degrees. This is crucial in applications where the input and output shafts need to be oriented differently.

- Power Transmission: 90 degree gearboxes efficiently transfer torque and power across the perpendicular input and output shafts. They can transmit substantial power while maintaining compactness.

- Multiple Gear Ratios: Some 90 degree gearboxes incorporate multiple gear stages, allowing for different gear ratios. This versatility is valuable for adapting to various speed and torque requirements.

- Reduced Complexities: Using a 90 degree gearbox can eliminate the need for additional components like couplings, universal joints, or belts that might be necessary when trying to achieve directional changes through other means.

- Alignment and Precision: These gearboxes maintain alignment between the input and output shafts, which is crucial for maintaining accurate and precise motion transfer.

- Reduced Maintenance: 90 degree gearboxes, when properly designed and maintained, can offer reliable and long-lasting operation, reducing the frequency of maintenance and downtime.

- Customization: Manufacturers often offer a variety of 90 degree gearbox configurations, enabling customization to specific application needs.

Due to their versatility and advantages, 90 degree gearboxes are widely used in industries such as automotive, manufacturing, robotics, aerospace, and more.

90 degree gearbox for your application involves considering several factors to ensure optimal performance and efficiency. Here are the steps to guide you:

- Identify Load Requirements: Determine the maximum torque and power requirements of your application. This will help you select a gearbox that can handle the load without exceeding its capacity.

- Calculate Speed Ratios: Calculate the required speed ratios for your application. Consider both input and output speeds to ensure the gearbox can achieve the desired output with the available input.

- Consider Space Constraints: Measure the available space for the gearbox. Choose a size that fits within your machinery or equipment without causing interference.

- Choose Gearbox Type: Based on your application’s requirements, choose the appropriate type of 90 degree gearbox. Consider factors like efficiency, backlash, and load distribution.

- Check Efficiency: Evaluate the efficiency of the gearbox. Higher efficiency gearboxes reduce power loss and improve overall system efficiency.

- Consider Mounting Options: Determine how the gearbox will be mounted within your system. Consider factors such as orientation, shaft alignment, and attachment points.

- Consult Manufacturer’s Data: Review the manufacturer’s specifications and data sheets for the gearbox options you’re considering. This information will provide details about torque capacity, speed ranges, and other technical specifications.

- Consider Overload Conditions: Factor in any potential overload conditions that may occur in your application. Choose a gearbox that can handle occasional overloads without permanent damage.

- Factor in Future Growth: If your application may experience growth in the future, choose a gearbox that can accommodate increased load and speed requirements.

By carefully considering these factors and consulting with gearbox experts or manufacturers, you can select the right size 90 degree gearbox that meets your application’s needs and ensures reliable and efficient operation.

editor by CX 2023-08-23